Innovative, practical,

cutting-edge R&D projects

About Signetron

Located in the heart of Silicon Valley, Signetron has been providing high-tech, cutting-edge solutions to government agencies and companies since 1992.

We deliver innovative solutions to the world’s toughest challenges, ranging from green buildings and climate change to autonomous drones and robots to protect and serve U.S. soldiers in the field. We design and develop end-to-end hardware and software systems by leveraging the latest techniques in AI/ML deep learning, computer vision, signal/image/video processing, and 3D spatial computing.

Green Buildings

Energy audits

Energy efficiency improvements to buildings reduce energy consumption & improve occupant comfort. Building managers use energy audits to identify areas where a building may be losing heat or wasting electricity. However, current audit procedures are costly & imprecise, requiring significant time and labor to complete. New ways to accurately, rapidly, & inexpensively capture energy-relevant data & assemble building energy models can empower building energy managers to better understand sources of energy loss in their buildings and determine the most effective retrofits for improving energy efficiency.

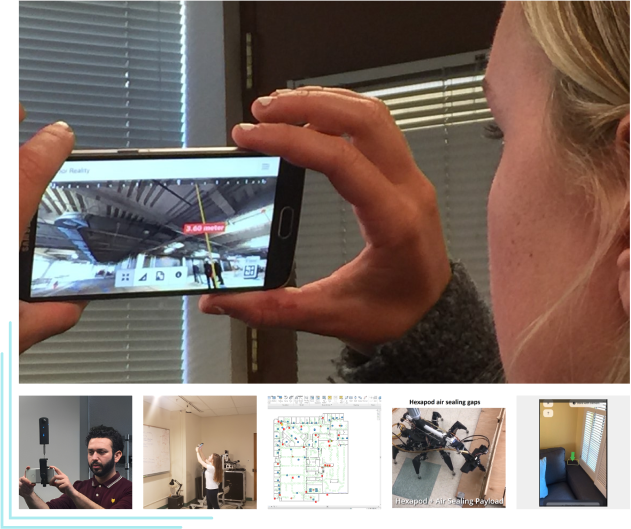

Over the past decade, Signetron has developed technologies to enable fast, accurate, & cost-effective audits without the need for expensive, skilled labor to collect data manually. Signetron’s innovation integrates low-cost visible and infrared optical cameras into a handheld scanner with depth sensing. This enables the operator to capture indoor 3D maps of building geometry and energy-relevant features as they traverse a building. Captured data is uploaded to the cloud where it is analyzed by Signetron software to generate an energy model and provide actionable energy audit information. This technology reduces the time and cost associated with today’s energy audits by 10× while offering actionable energy-saving recommendations. It lowers the cost barrier for building energy audits, enabling property owners and facility managers to better understand the sources of energy loss in their buildings and where to optimally target retrofits to improve energy savings.

Green Buildings

Envelope Retrofits

Signetron has developed a range of solutions for making envelope retrofits faster, easier, and more affordable

PaTER

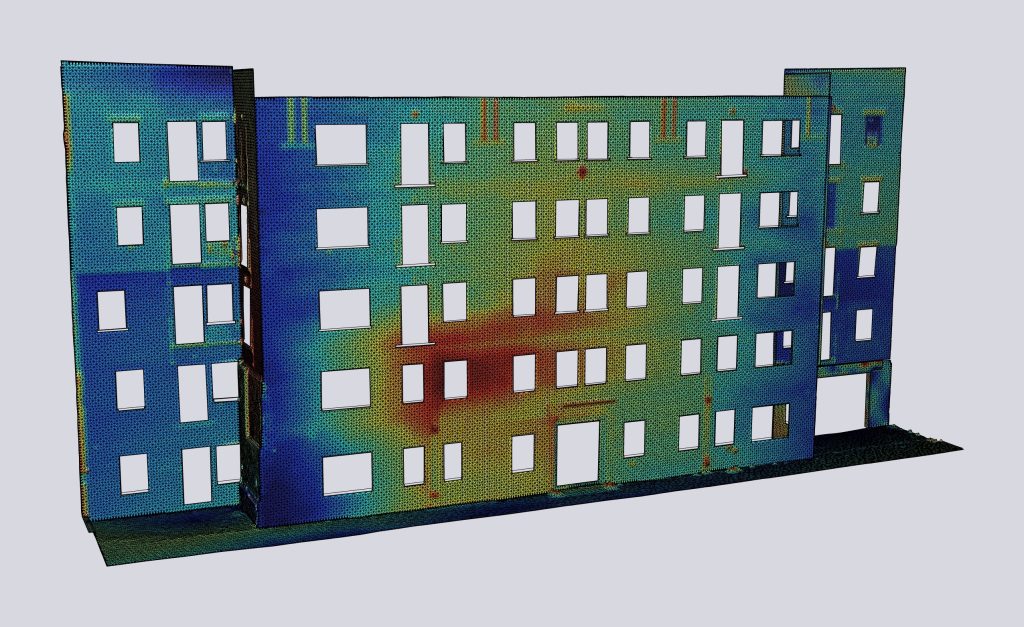

PaTER turns point clouds into ultra-accurate building models that properly capture warped and buckled facades and other non-idealities.

TAPoC

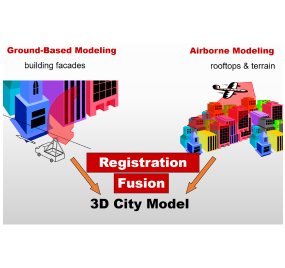

TAPoC identifies holes in point clouds captured by terrestrial laser scanners and precisely fills them with points captured by aerial LiDAR units.

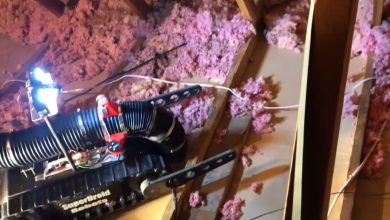

RoboAttic

Signetron won Phase 1 and Phase 2 of the E-ROBOT competition sponsored by the U.S. Department of Energy in 2021 and 2022.

Thermography

Thermography

Signetron has developed robot– and drone-based thermography systems for assessing the thermal performance of buildings

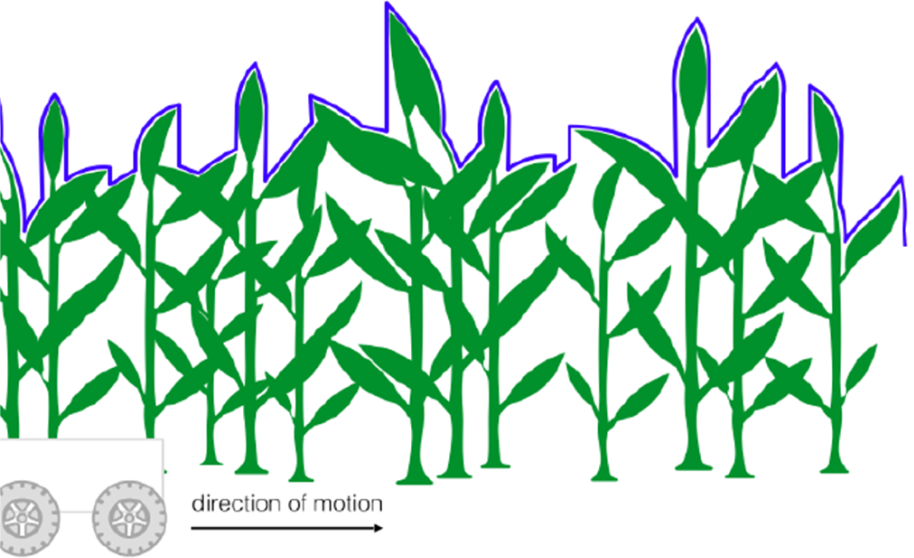

Autonomous thermographic robot roaming inside buildings

Drones & Robotics

drone thermography

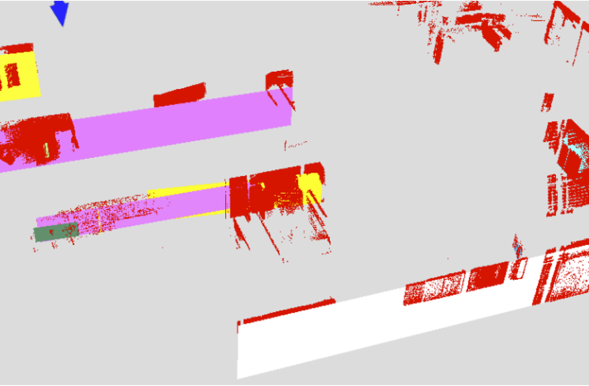

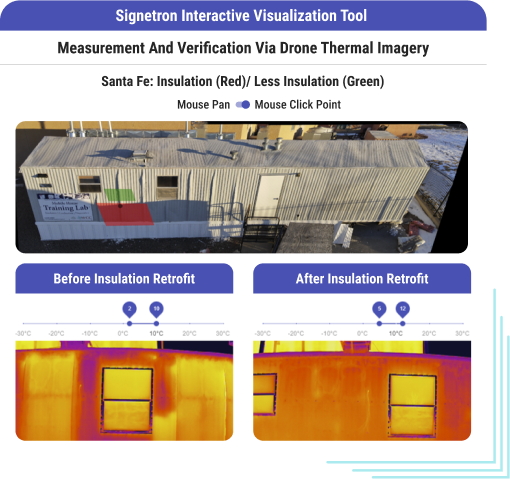

Signetron Interactive Visualization tool can be used for Measurement and Verification (M&V) of structures that have undergone retrofit. For larger buildings, ideally one would like to capture the thermal pictures up close in order to capture the details of thermal anomalies. However, the close up pictures necessarily make it difficult to determine which part of the building each picture came from, due to lack of context. SIV tool solves this problem by first generating a “synthetic” panorama of the façade. Next, as the user clicks on any part of the façade panorama, the thermal picture corresponding to that point is automatically displayed. Furthermore, if there were multiple drone captures for example, corresponding to before and after insulation retrofit, they are displayed side by side allowing for rapid, qualitative M&V process. Our tool allows all stakeholders including the contractor and the owner to view the before and after pictures immediately after a retrofit to pinpoint and remedy flaws. This significantly improves current envelope retrofit M&V, which is (a) lumped with mechanical systems; (b) takes two years of reviewing utility bills; (c) does not pinpoint flaws such as missing insulation.

Robotics & Drones

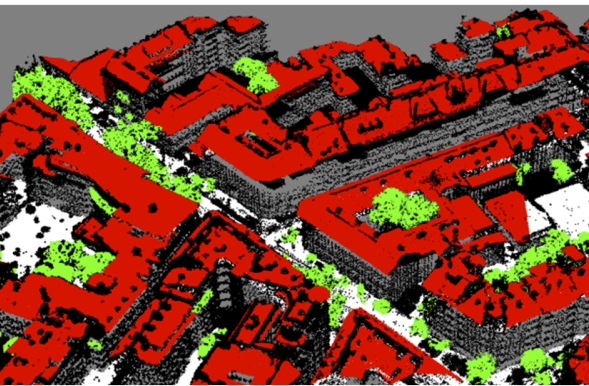

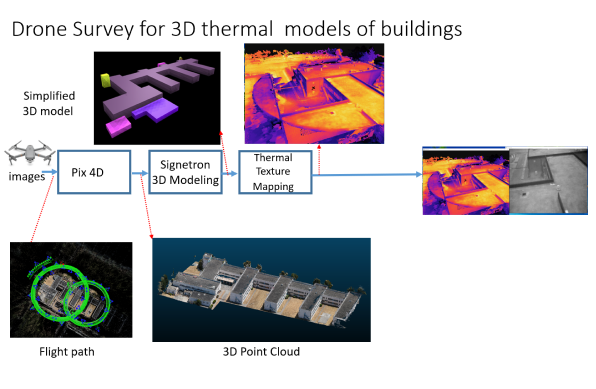

Drone Survey for 3D Thermal Models of Buildings

Building energy audits are time-consuming and labor-intensive. We have developed a new method using machine learning (ML) techniques on novel data sources (drone images) to improve the identification of building characteristics and retrofit opportunities, and thereby reduce the effort for audits. The new ML method includes: (1) Building footprint extraction using line extraction, polygonization, and polygon-merging, (2) Building envelope extraction using PIX4d modeling software to reconstruct a building 3D model, (3) Visualization tool for viewing images from the 3D model, (4) Window-to-wall ratio (WWR) using state-of-art deep neural network semantic segmentation, (5) Envelope thermal anomaly detection using an unsupervised machine learning clustering algorithm, and (6) Rooftop energy equipment detection based on an object detection algorithm.